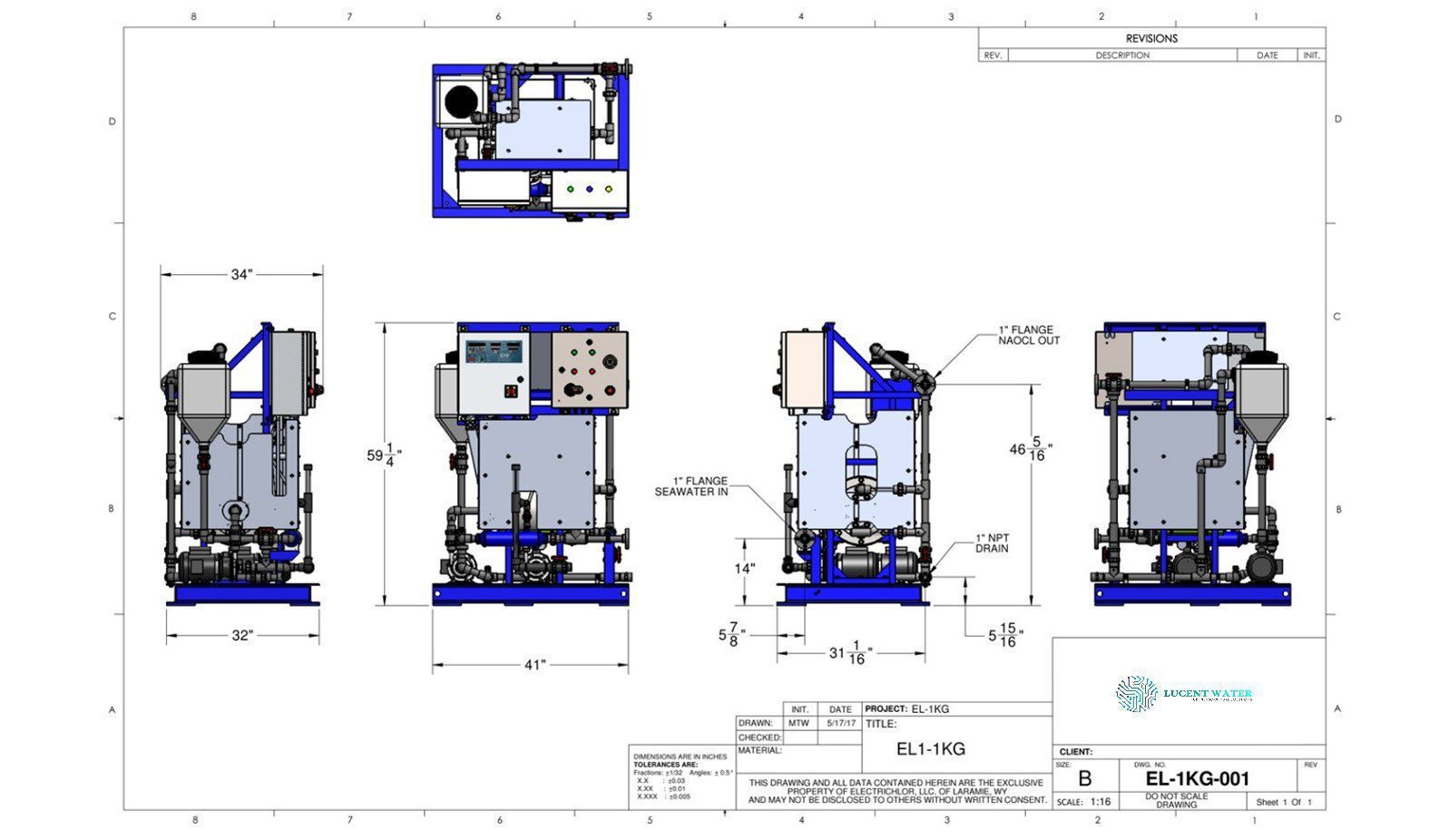

Electrolytic Chlorine Generators

Avoid spending hundreds of thousands year after year on expensive chemicals for dosing and start generating your own hypochlorite solution on-site for a fraction of the cost!

Our electrolytic cells are many times more efficient than the competition due to the patented configuration that allows a progressively longer residence time for the adsorption of Chlorine into the outgoing hypochlorite solution.

All of our Electrolytic Chlorine Generators are guaranteed against defective parts for 18 months from startup and for 5 years for the MMO anode coating under normal operating conditions. Each cell uses normal seawater or salt-brine and is set to deliver up to 2000ppm of equivalent chlorine!

Each generator is equipped with an individual control system. This allows each unit to be operated independently and individually from its control station or remote location.